1U Utilfo: Build document

The Foxfield Instruments UtiLFO is a 1U Utility LFO. It generates both triangular and square waveforms, frequency controlled by knob on the front.

Like all Foxfield Instruments' tiles, it’s specifically designed for DIY assembly.

The UtiLFO is designed using surface-mount components (“SMD/SMT”). It all may look small, but with a little patience you’ll be fine. That said, we definitely do not recommend this as your first DIY kit. You should be reasonably confident with a soldering iron before moving onto SMD kits. If you’ve built a few kits and know your way around a soldering iron, though, you should be fine.

If you’re interested in what it’s like to build, or concerned about surface mount components, we have a video of it being built:

FOXFIELD TILES ARE NOT COMPATIBLE WITH INTELLIJEL 1U SYSTEMS. Apologies. We write this in bold quite a lot. There’s more in a footnote if you’re interested why.

Table of Contents

- Specification

- What’s in your kit

- What you’ll need to build your kit

- Before you begin

- How to solder SMD components

- Building your kit

- Connecting your tile to power

- Usage ideas

- Extended credit: changing the LFO range

- Appendix

Specification

- Format: “Pulp Logic 1U” - NOT COMPATIBLE WITH INTELLIJEL 1U SYSTEMS

- Power connector: Pulp Logic “Tile Tail”.

- Width: 6HP

- Power consumption: ~10mA +12V, ~10mA -12V

- Triangle Wave output about +/-5V peak to peak

- Square Wave output about +/-8V peak to peak

- Frequency: ~100mhz to ~20hz

What’s in your kit

Inside the paper bag are some small plastic bags. To avoid confusion around resistor and capacitor values, we’ve separated out components that might otherwise be confusing. If there are identical looking components, count the number on a strip; you should never have two components that can be confused.

We would not recommend tipping all your bags out into the same space; you will get confused. Remove components as you need them. Similarly, do not remove components from their tape until you’re ready to attach them - the components are very small.

| Quantity | Part | Marked/Description | Location |

|---|---|---|---|

| 2 | 100n capacitor | yellow, no numbering | Bag A |

| 1 | 10k resistor | `1002` | Bag A |

| 2 | 10u aluminium capacitor | Small metal can | Bag A |

| 2 | Fuses | Small oblong with `B` on it | Bag A |

| 4 | 1k resistor | `1001` | Bag A |

| 2 | Diodes | small black block with metal legs | Bag A |

| 1 | 470k resistor | `4703` | Bag A |

| 1 | 22k resistor | `2202` | Bag B |

| 1 | 47k resistor | `4702` | Bag B |

| 1 | 5.6k resistor | `5601` | Bag B |

| 1 | TL074 IC | Black chip with 14 legs | Bag B |

| 1 | 100k log potentiometer | Including nut and washer | Mechanical bag |

| 2 | 3.5mm mono Jacks | Including nuts | Mechanical bag |

| 1 | 5mm Bipolar LED | Mechanical bag | |

| 1 | PCB | PCB bag | |

| 1 | Panel | PCB bag | |

| 1 | Knob | Mechanical bag | |

| 1 | Tile tail | Paper bag | |

| 4 | M3 screws | Mechanical bag |

What you’ll need to build your kit

Foxfield Instruments kits may use surface-mount components, but they’re designed to be assembled by humans with hand-tools.

We list the tools we recommend that you’ll need on our DIY page.

How to solder SMD components

If this is your first SMD kit, you might want to go over our up-to-date guide to soldering SMD components. We’ve collated some videos and guides from around the web, which should prove instructive.

Before you begin

- Read through these instructions to get an idea of where you’re going.

- Dig out all the tools and equipment you’ll need. Having things ready is better than diving into doors with a busy workbench.

- Clear your workspace.

- (optional) Make a cup of tea. Don’t keep it too near the workbench, but tea always makes DIY go easy.

- Get your soldering iron up to temperature.

- OK, let’s begin!

Building your kit

Throughout this build document, we’ll refer to the front and back of the PCB. The front is where the jacks and pot go: it’s got the outlines of them on it. The back is where the majority of the components are, and where the Foxfield logo is.

We’re going to start with the back of the board.

1. IC (TL074 op-amp)

Solder the op-amp first.

Much like through-hole, we solder SMD components in height order - lowest to highest. However, with our tiles, we make one adjustment to that build order: solder the IC first. It’s the hardest thing to solder, and it’s in the middle of the board - if we put it on now, we’ll have the most room to work.

The IC must be fitted in the correct direction. There are two clues to its directionality: the vertical line at one end of the silkscreen, and the horizontal line that intersects the pads at the lower edge of the board (towards the Foxfield logo). If your IC has a white line printed on the top, this maps to the thick line printed on the left of the IC silkscreen. Regardless, you’ll also notice - if you look at the chip end-on - that it has one slanted edge and one vertical edge. The slanted edge is also hinted on the PCB silkscreen with the thick long edge of the IC - in this case, it faces the Foxfield Logo.

2. Bottom Passives

Solder the 1206 passive components into the correct places

Now you’ve got the IC in, attach all the 1206-sized resistors and capacitors. These are all marked with their values; the two capacitors are marked 100n and have a C in the middle of their outline.

Our recommended routine for doing this would be:

- prep all the pads - solder on one side of the outlined shape

- attach all the 1206s facing in the same direction to their prepared pad

- solder up their other pad

- rotate the PCB 90º and repeat for all the 1206s in a different direction.

None of this components are directionality - back-to-front, upside-down, it doesn’t matter - although we’d recommend keeping the resistor values visible just in case you have to debug.

3. Topside: flat components

Solder the SMD components onto the top of the board

Flip the PCB over; we’re going to build up the top (the side with the jacks and pot outline on it). Now that you’ve got components on the back, you’ll need to find a way of firmly holding the PCB - just putting it on a tabletop or cutting mat is probably not enough. (A vice is really helpful).

Let’s do the flatter components first.

First, the fuses. These are marked F on the PCB and easily fitted on the left. They do not have a correct direction.

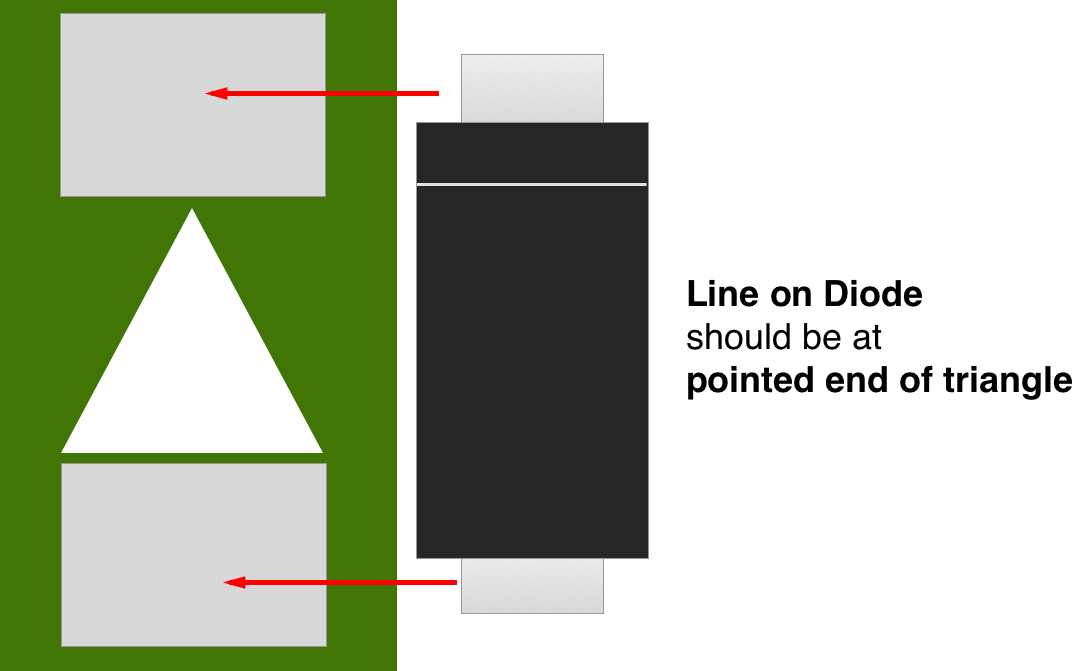

Next, the diodes. These must be fitted in the correct orientation. If you take the diode chips and look at them in good light - or shine a cellphone torch on it - you’ll see a line printed on the top, towards one end. These should go towards the pointed/narrow end of the triangles silked on the board. Imagine the line ‘completing’ the Diode symbol:

4. Topside: 10u capacitors

Solder the capacitors onto the top of the board.

Now we can fit the 10u capacitors. These must be fitted in the correct direction. Fortunately, that direction is outlined for us on the board: the base is asymettric, and the black line on the top of the cap should match the black line on the board. They might seem a bit fiddly to solder on, but trust in the flux and you’ll be fine.

5. Topside: through-hole components

Solder all the through-hole components, being careful to align them with the board.

NB: the correct potentiometer for the UtiLFO is a 100K log potentiometer - “A100K”. Owing to a mistake, your board may be marked B100K - however, the potentiometer supplied with your kit will be correct. Just fit it as normal.

Now we’ll fit the jacks, pot, and LED. This will probably be familiar from many other through-hole builds, but as a reminder:

- remove the nuts from the jacks and potentiometer.

- put the LED in its marked hole and do not solder it. The flat edge of the LED is marked on the board (on the inner side).

- put the pot into the board. Its little green feet should be pressed against the board. You may have to flatten, jiggle, or trim the wide ‘legs’ on it to go through the mounting hole. They should snap into place with the pot standing against the PCB. (These legs are for support; it’s the three pins at the top that matter electrically). Once it’s in: do not solder it.

- Place the jacks into their marked positions and do not solder them.

- Take the front panel of the board and mount it onto the jacks and pots. It should fit neatly, becoming parallel to the PCB, and pushing down til it’s at the top of the jack bodies. When you’re satisfied with its positioning, screw the jack nuts and the potentiometer nut to hold them to the front.

- Confirming that the components are still flush to the board, flip the PCB over and solder them in place.

- Now maneouvre the LED so it sits in its hole at a height you’d like. Solder it in place and trim its legs.

6. Tile tail

Fit the power connector.

Finally, we need to fit the power connector. To do this: remove the front panel.

Separate the three wires at the end of the tail and strip them with your wire strippers.

Next, tidy and tin the ends: twist stranded core of each wire together and tin it with your soldering iron. Do not think you can get away without tinning wires. It will make your life way easier.

Insert the tile tail into the board. Tile tail power is configured as follows:

- black - GROUND

- red - +12V

- white - -12V

These are marked on the rear of the PCB - the ground is the square pad at the bottom of the board. Attache the wire so that it goes through from the base, and you solder it on the top-side of the board.

Trim its ends, and re-mount the panel.

7. Knob

Finally, attach the knob to the potentiometer, securing it in place with a set screw.

8. That’s it!

You’re done. You’re ready to power up your tile and test it.

Connecting your tile to power

At Foxfield, we'd **always** recommend powering up a new DIY build as the only thing connected to a power supply.Tile-tails are keyed; you can't power them up the wrong way. Just connect the connectors so they're firmly linked, and coloured cables match up.If you’ve got a bench supply or testing supply, that’d be ideal (you’ll need a dual-supply +/-12V for the LFO tile).

Of course, you don’t have to - and many people don’t - but we’d hate to see your modular come to grief through DIY errors.

When turned on, you should see the LED alternating between green and red; it’ll get faster as you turn the knob clockwise, slower as you turn anti-clockwise. This is the triangle-wave output. The square-wave output is a signal derived from this - it goes at exactly the same rate.

Enjoy your new tile!

Usage ideas

- Use the triangle wave as an LFO to control modulation on other modules - filter cutoffs, waveshapping, VCAs

- Use the utility LFO to modulate the rate of another LFO in your system: complex modulation ahoy!

- Use the triangle output as a modulation source whilst also using the square wave as a clock source: tempo-synced modulation. (You could feed the square wave into a clock-divider, too, for syncing a faster LFO wave to a slower - but still rhythmically relevant - clock).

- Feed the square wave into a Foxfield GT2 Gate-to-Trigger converter to turn it into a short pulse, ideal for plucking an LPG.

- Use an attenuator (such as a Foxfield Averter), an offset, or a rectifier, to scale or offset the LFO output to your needs.

Extended credit: changing the LFO range

The LFO range is controlled by the interaction of the 470k resistor and the 100nF capacitor. If you’d like a shorter LFO time, you can swap out the resistor for something lower - our early prototypes used a 220k resistor and were slightly too fast for the majority of the knob’s throw. If you’d like slower times, bump it up a little. 470k felt like a good middle fit.

Appendix

“Why don’t you support Intellijel 1U?”

Space, and personal design choices.

Intellijel 1U doesn’t just have a smaller frontpanel: it also has a smaller space between the rails for a PCB. We didn’t feel we could fit enough components onto a parallel PCB that would fit comfortably into Intellijel’s format; we decided against multi-stacked boards. The Foxfield 1U series fit what they can onto a single PCB.

Currently, pretty much all 1U DIY seems to be focused on the Pulp Logic (and Erthenvar/Synthrotek) format, so we thought we’d stick to that.

There’s also a philosophical distinction: 1u “tiles” focus on small, single-purpose, 6HP or 12HP objects; Intellijel’s 1U modules focus on wider, sometimes multi-functional units.

We appreciate this is a shame given the likely popularity of Intellijel 1U; we also suspect that Intellijel will be making a handsome and useful range of their own 1U modules, that many purchasers will be entirely satisfied with.

Needless to say: we may revisit this distinction in the future.

“What’s the different between Intellijel 1U and Pulp Logic 1U?”

The difference is: how you measure the 1U.

Pulp Logic style tiles (such as Foxfield tiles) are designed for use with lipless rails, and measure 1U from the top of the top rail to the bottom of the bottom rail.

Intellijel 1U tiles are designed for lipped rails, and measure 1U from the top of the top lip to the bottom of the bottom lip. As such, the tile panel, and gap between the rails, is smaller than Pulp Logic.

Eurorack doesn’t really have any standards; it has conventions. This is a case where two conventions emerged separately.